IntroductionYPG Series ressurized spraying and granulation dryer is suitable for Food industry, Pharmaceutical industry, Plastics and resin, Detergent, Chemical industry, Ceramic, etc.

Because of different products have different drying technologies and particle rules, there is no single type of the spray drying machines that meet all kinds of different requirements. Now spraying is still regards as a kind of technology. The test is the base of correctly choosing the types. The machine equipped by the CONOVAL GROUP LIMITED is used specially for the carry out the technological test of the materials. This kind of practical manner makes that we have completed many turn-key projects, such as: detergent powder, polymerized resin, white carbon,Mn3O4,soybean milk, lipase, sea cucumber Chinese traditional medicine and etc.

Related Links

- View a Flash show (Full edition)

40KB

40KB - Get Flash Player to read FLASH file

Electric control panel

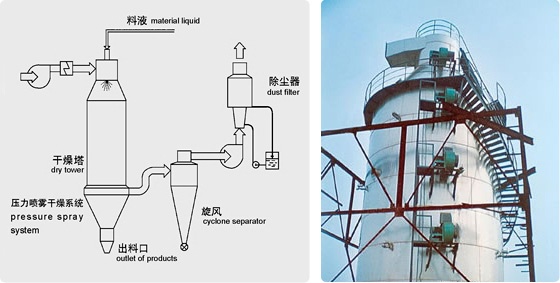

The material is sprayed into fine mist by nozzle on the top of tower. Follow the heat wind, the material is dried. The machine's characteristic is high collection rate, no stick onto the wall, energy saving, high efficiency, especially applicable for heat sensitive material. It's widely used in food, dyestuff, chemical industry and so on.

Flow chart

Application

- Food industry: Fatty milk powder, protein, cocoa milk powder, subsitute milk powder ,egg white (yolk), food and plant ,oats ,chicken juice, coffee ,instant dissoluble tea ,seasoning meat ,protein ,soybean ,peanut protein, hydrolysate and so forth .Sugar, corn syrup, corn starch, glucose. pectin, malt sugar, sorbic acid potassium and etc.

- Pharmaceutical industry: Traditional Chinese medicine extract ,ointment, yeast, vitamin, antibiotic, amylase, lipase and etc.

- Plastics and resin: AB, ABS emulsion, uric acid resin, phenolic aldehyde resin, urea-formaldehyde resin, formaldehyde resin, polythene, poly-chloroprene and etc.

- Detergent: common washing powder, advanced washing powder ,soap powder, soda ash, emulsifier, brightening agent, orthophosphoric acid and etc.

- Chemical industry: Sodium fluoride (potassium ), alkaline dyestuff and pigment, dyestuff intermediate, Mn3O4, compound fertilizer ,formic silicic acid ,catalyst, sulphuric acid agent ,amino acid ,white carbon and so on.

- Ceramic: aluminium oxide, ceramic tile material, magnesium oxide, talcum and so on.

- Other: Calmogastrin, hime chloride, stearic acid agent and the cooling spray.