IntroductionCT-C Series used in raw material medicine, herbs, herbal medicine, powder, granule, powder, medicine bottles, salt, wool, paper, size of the pill bottle, pigment, dyestuff, dehydration vegetable, dried fruits, melon seeds, sausages, plastic resin , electrical components, baking and catalyst.

CT series hot air circle oven is equipped with low noise axial flow fan and automatic temperature control system, the circulatory system all closed, so that the thermal efficiency of oven drying room from the traditional 3-7% to the current 35-45% The maximum thermal efficiency up to 50%. CT series hot air circle oven design success, I plant the hot air circulation oven reached the international advanced level, in order to save a lot of energy, improve the economic efficiency of enterprises. State Pharmaceutical Administration in 1990 issued the industry standard, uniform type is RXH.

Features

- Most of the hot air inside the loop, high thermal efficiency, energy conservation.

- The use of forced ventilation in the box with adjustable air board, dry materials evenly. Source may be steam, hot water, electricity, far infrared, a wide choice.

- The machine has low noise, stable operation. Temperature controlled, easy installation and maintenance.

- Wide application and can be used for drying various materials and is a common drying equipment.

Related Links

- View a Flash show (Full edition)

40KB

40KB - Get Flash Player to read FLASH file

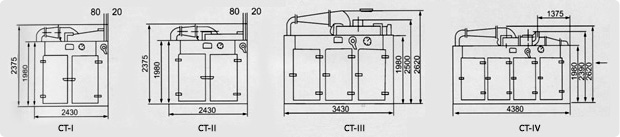

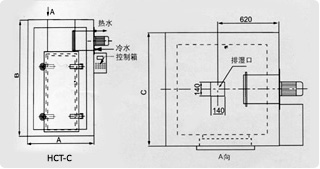

- View all drawing

246KB

246KB

Related Model

Applications

Hot air circulation boxes for the pharmaceutical, chemical, food, agricultural and sideline products, aquatic products, light industry, heavy industry materials and products such as heating and solidification, drying dehydration. Such as raw materials, Chinese traditional medicine, Chinese Herbal Medicine, extract, powder, granule, powder, water pills, bottles, paint, dehydrated vegetables, dried fruits, melon seeds, sausages, plastic resin, electric elements, drying varnish and so on.

The main technical parameters of hot air circulation box and instructions

- 1. the heating source of steam, far infrared, dual-use steam power for the user to choose.

- 2. the use of temperature: steam heating 50-60 ℃, maximum 150 ℃.

- 3. electricity, far infrared temperature of 50 ~ 350 ℃.

- 4. in both automatic and computer control systems for customer choice.

- 5. used steam pressure 0.2 ~ 0.8MPa (2 ~ 8kg).

- 6. with electrical heating by a computing 15kw, practical 5-8Kw / h.

- 7. show that the special requirements when ordering.

- 8. non-standard oven price is negotiable.

- 9. temperature greater than 140 ℃ or less than 60 ℃, to specify when ordering.

- 10. drying cars, baking tray size of unity, can be interchanged.

- 11. baking tray size: 460 × 640 × 45.