IntroductionAs a Professional glass lined reactors manufacturer, CONOVAL GROUP dedicated in manufacture many kinds of glass lined equipment and other corrosive system, to pharmaceutical, chemical and processing industries.

Applied with high corrosive resistance characteristics technology glass lined reactor manufacture; this achieved the reactor with highly corrosion resistant, chemical inert, as ideal equipment for different processing environment.

Professional and experienced technical team, provide unique project for each customer according to their different technical process request.

We provide unique project for each customer according to their different technical process request.

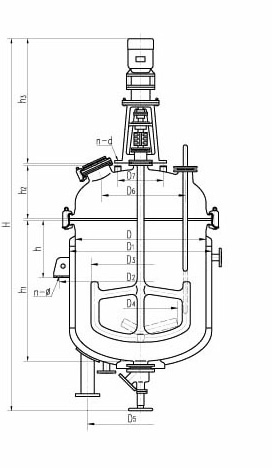

Chemical glass-lined equipment is a kind of vessel whose main body is made of high quality carbon steel lined with special silicate glass by fritting as a high temperature. It has mechanical strength like steel-made vessel. It is irreplaceable with stainless steel, engineering plastic and other alloy steel materials under a certain medium and temperature at corrosion resistance. It is also indispensable and economic and good corrosion resistance equipment (for hydrolysis, neutralization, crystallization distillation evaporation and storage) in industries of production of pharmacy, chemical, dyestuff, organic synthesis, foodstuff, pesticide and defense.

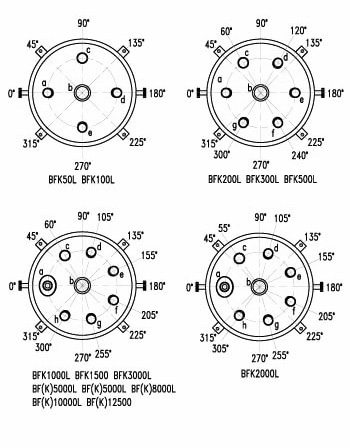

Our company has a long history in manufacturing glass-lined equipment, and accumulated rich experience at management and manufacturing. We have established a complete strict set of systems of research, development and quality guarantee. Now our company owns a design center of glass-lined vessel, a technical study center, three fritting electric furnaces controlled by computers and a full electric melting furnace of glaze material. The technological and physical properties of glass-lined glaze have reached the internationally advanced level and we can manufacture various reactor and storage-tank of 50L - 20,000L. We also can manufacture various specifications of stainless steel reactor and storage tank.